Products

Can be designed as Cladding or engineered to transfer shear

can be fabricated on site using common tilt-up procedures.

With 33% of energy loss in the U.S. occurring through heating, cooling and operating commercial buildings

MSC floors and roofs can be engineered from light-gauge steel joists.

MSC panels are ready for utilities and insulation in stud cavities..

MSC panels integrate light-gauge metal framing with thin-shell.

Light-weight MSC concrete panels are fabricated to match the texture.

Lighter weight Metal Stud Crete® panels may contribute toward achieving additional LEED points

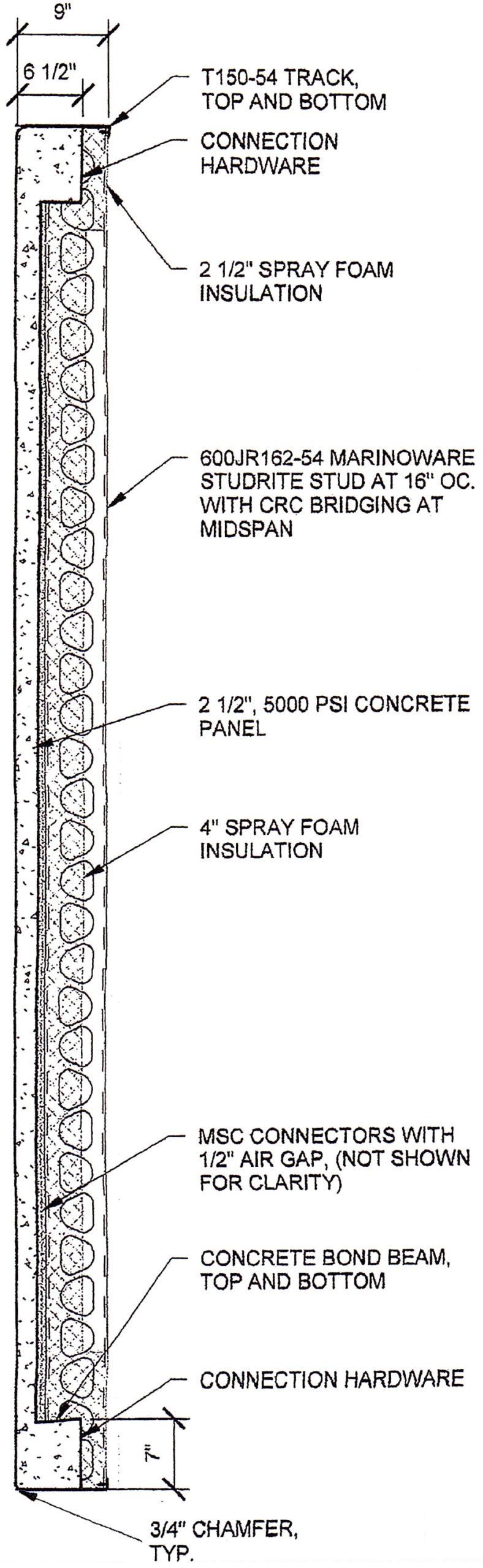

Framed and Insulated Concrete Wall Panels

With 33% of energy loss in the U.S. occurring through heating, cooling and operating commercial buildings, MSC Insulated Panels can save on energy Costs.The ASHRAE 90.1 2007 and the IECC 2009, 2012 and 2015 energy codes call for continuous insulation to reduce thermal bridging when pre cast is connected to another superstructure.

The Metal Stud Crete Insulated Pre Cast panel system is your best choice for commercial projects that require greater energy efficiency, to meet or exceed the IECC building code. The Framed and Insulated Pre-cast Panel System provides a unique union of technologies that together are superior to conventional systems.

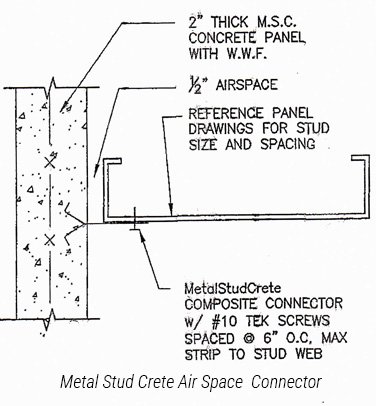

Each pre-cast panel is a combination of a thermally resistant open web steel stud and a Metal Stud Crete connector that separates the framing from the pre-cast concrete when spray on foam insulation is continuously applied to the inside of the panel. The insulation then flows between the concrete and the framing, and through the openings in the studs to create a thermal break. The Air Gap between the framing and the concrete can be adjusted to accommodate up to 1” of R-7.5 continuous insulation. This panel assembly uniquely combines steel stud framing, insulation, and pre-cast concrete into a cladding system for use as a building enclosure . Each panel is pre-cast and cured in a factory environment for consistent dimensional accuracy, finish uniformity and exceptional quality control.

Attributes of the Framed & Insulated Pre-cast System:

- Meets IECC 2015 requirement

- Framing, insulation and cladding in one step

- Ideal for building types that require finished interiors and superior energy efficiency

- Uses 65% less concrete. Thickness can be adjusted based on design requirements

- Specified in any color or texture

- Open cavity for easy installation of mechanicals

- Pre-framed panels increases floor area by eliminating furring

- Designed and engineered for the project

- Lighter dead loads reduce structural design requirements

- Pre-finished exterior with cladding of choice

- Steel stud ready for drywall

- Produced in precast plants nation-wide